BIOREL is the new family of materials for "environmentally friendly" footwear construction, as it meets the biodegradability requirements of European and American standards CEN EN 13432 and ASTM D 6400.

Its composition is 95% biodegradable and compostable polymers and 5% biodegradable natural cotton.

It is manufactured by transforming polymers derived from renewable sources, where natural starches were incorporated to allow for complete biodegradability. After 60 days in composting conditions, BIOREL loses more than 87% of its total weight.

The behavior of the materials was also certified by the specialized institute OWS from Gent, Switzerland.

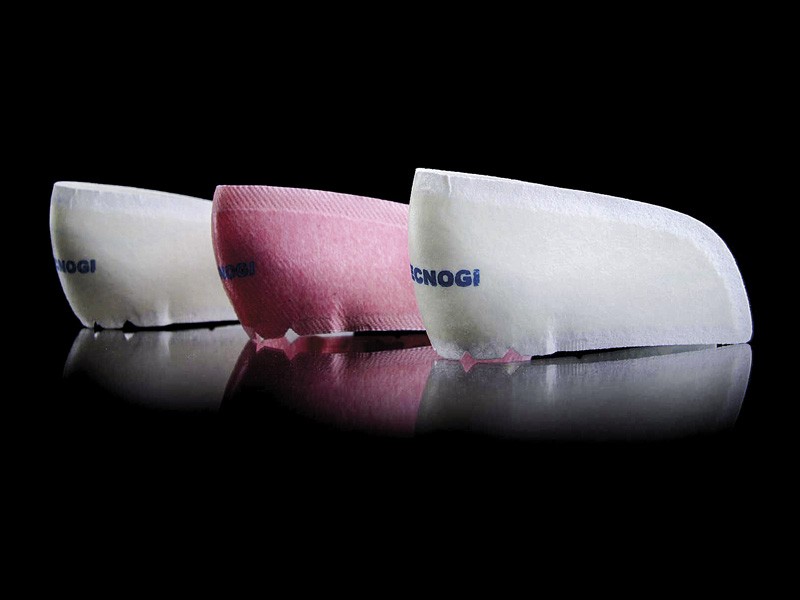

Among its main advantages are its greater flexibility, elasticity, and moldability, which can be obtained at room temperature or after heating the material. These particularities allow footwear made with these toe caps and counters to considerably improve their comfort, in addition to offering a correct copy of the last and a long durability.

They come in different thicknesses, depending on the product to be manufactured.

They are very malleable to work with and have an optimum open time.

They can be applied using a fusion press with curved plates equipped with a timer and thermostat.

The recommended application method is:

• Temperature of the shape: 150-170°C

• Minimum effective interface temperature: 100°C

• Contact time: 5 to 10 seconds depending on the thickness of the toe cap.

Assembly: it is recommended to use a hot last or steamer at a temperature of 80°C, which is ideal for reactivation before assembly.

The cut and skived counter can be heated on a hot plate or on a flash activation machine until it becomes soft and flexible before inserting it into the counter pocket -between the upper and lining-. It can be semi-molded to the shape of the backseat and fixed with finger pressure applied along the upper and lining. The backpart is completed by forming on warm molds of a backpart molding machine, with temperatures and dwell times to give a minimum interface temperature of 100°C. This, and dwell times, can be adjusted to the requirements of the upper and lining material. The back part remains soft for 2-3 minutes after removing it from the hot molds. It may be necessary to reheat for a final molding.

The cut, skived and molded counter is inserted loosely like a conventional thermoplastic material and preheated by activating the clamp for 5 to 10 seconds at 130°C. The temperature and dwell times can be adjusted to the requirements of the upper and lining materials, until achieving a minimum interface temperature of 100°C. The heated upper is molded and flanged on refrigerated molds for 10 to 12 seconds. Assembly is completed as for a conventional thermoplastic counter, it may be necessary to reheat for seat lasting.