It is an equipment created to meet the needs of placing labels, with brands, characteristics, data and QR on finished products and their parts. In footwear, for example, it is very common to label insoles and tongues.

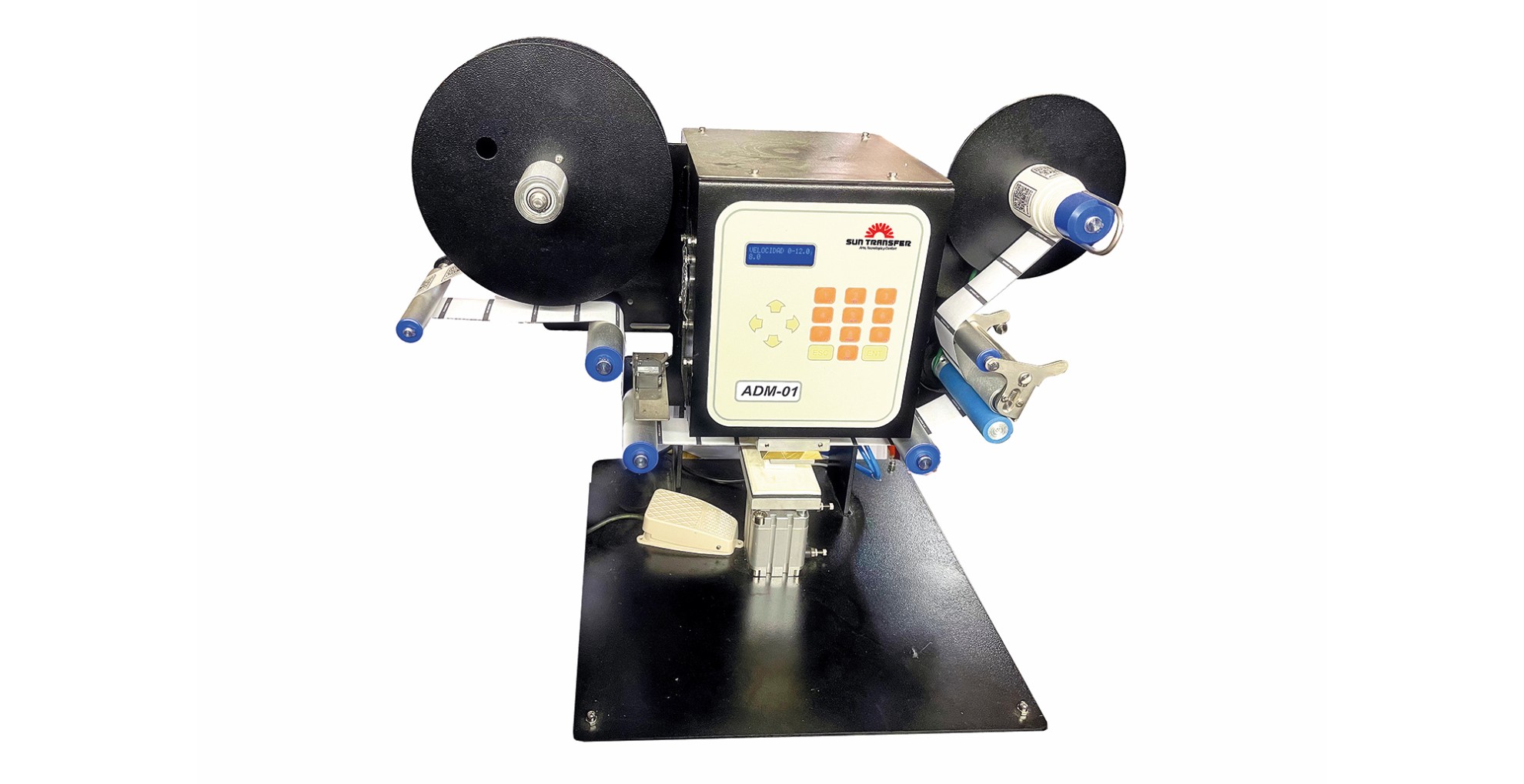

SUNTRANSFER's ADM-01 model is a self-developed device that is compact, versatile, easy to use and effective production.

Functioning

It consists of an applicator head, which by means of pressure and temperature, fixes the labels on different natural materials -leather-, synthetic and textiles, which make up the pieces. The labels are previously printed on reels, which with an automated transport system, are positioned as programmed on the material to be labeled. It is a thermo-pneumatic process, by which the label adheres to the material in a programmed time cycle. It is an action by pressure and temperature, in a unit of time pre-established by the user.

Label application on textile material

Automatic and programmable

All the parameters of the operation are regulated from the CPU based on the characteristics of each material where the label will be applied.

Once this application has been completed on the material, the computer proceeds to prepare the next label to be applied. This is done through a drag and transport system executed by a stepper motor, whose speed and distance are also adjustable from the CPU. The next label is located through an optical reader, which generates a signal that, upon reaching the CPU, orders its application.

Programming control to automate processes

Previous tests

To make the label, its characteristics are determined based on the material where it will be applied. It is recommended to carry out the pertinent previous tests to ensure that the material supports the temperature necessary for the transfer. From there, the configuration of the label is established, in its aesthetic and informative aspect, which includes logos, sizes, composition, washing method, QR code and other product data.

The system allows a safe transfer and adhesion of the labels on the different materials, however, it is necessary to carry out quality tests in advance to ensure high resistance to abrasion, washing and the different actions that are exposed during its use and application. It is essential, for example, in the case of textiles, to carry out adhesion tests, for which SUNTRANSFER's commercial department has all the equipment to carry them out and provide the greatest security to its customers.

Measurements and productivity

The maximum size of the labels is 10 x 10 cm, the number of colors depends on the design, which is generally up to 4 colors.

The estimated production of the machine, in an 8-hour shift, is 10,000 labels, in the case of shoe insoles.

Labels placed on insoles

Do you have information to share?

It is the opportunity to reach your customers!